Custom 24V Lithium Battery Pricing

Custom 24V Lithium Battery Pricing

The price variation for custom 24V lithium batteries fundamentally stems from “base cost + functional cost + customization cost + compliance cost.” This can be broken down into five core dimensions, with each dimension's impact on pricing and quantitative reference as follows:

(1) Cell Type & Brand

1. Differences in Chemical Systems

Lithium Iron Phosphate (LFP): Low raw material costs (stable lithium and iron prices), with overall costs 20%-30% lower than ternary lithium.

Ternary Lithium: Relies on precious metals like nickel and cobalt, with volatile raw material prices. Costs increase with higher nickel content (e.g., NCM811 is 15% more expensive than NCM523).

2. Battery Cell Brands & Grades

Differences in battery cell brands:

International brands: Such as Samsung, Panasonic, LG, etc. Due to high consistency and extended lifespan (10%-20% longer cycle life than domestic brands), prices are 30%-50% higher than domestic first-tier brands.

Domestic Tier-1 Brands: Examples include BAK, LiShen, and EVE Energy. These offer balanced cost-performance ratios, priced 30%-50% lower than international brands and 10%-20% higher than domestic second- and third-tier brands.

Battery Cell Grading Differences:

Grade A Cells (New and Certified): Stable performance (capacity deviation ≤2%), highest price point, preferred for industrial equipment;

Grade B Cells (Minor Imperfections): Slightly lower capacity/voltage consistency (3%-5% deviation), priced 20%-30% lower than Grade A, suitable only for low-demand scenarios;

Refurbished/Secondary Cells (Used/Retired): Lowest price (over 50% lower than Grade A), but short lifespan (≤500 cycles) and high safety risks. Not recommended for industrial-grade equipment.

(2) BMS Functional Complexity

1. Protection Board Types

Hardware Protection Board: Supports only basic overcharge/over-discharge/overcurrent protection with fixed, non-adjustable parameters and lower cost.

Software Protection Board: Supports programmable parameter adjustments and can integrate with device communication monitoring (e.g., power display, fault alerts). Requires development of software logic and communication protocols, resulting in a cost 50%-120% higher than hardware protection boards.

Hardware + Software Board: Combines the reliability of basic hardware protection with the flexibility of software parameter tuning and communication capabilities. Dual development costs result in a price 80%-180% higher than hardware protection boards.

2. Equalization Function Types

Passive Equalization (Discharge-Only Equalization): No additional cost, suitable for small batteries ≤50Ah capacity;

Active Equalization (Bidirectional Charge/Discharge Equalization): 30%+ cost increase, extends battery life by 15%, recommended for ≥100Ah capacity or scenarios requiring high consistency (e.g., medical equipment).

3. Advanced Expansion Features

Special communication protocols (e.g., CAN bus, SMBUS): RMB 20-50 per set surcharge, enabling device central control integration;

Battery level display (LED/LED display): RMB 10-30 per set surcharge, facilitating on-site maintenance.

(3) Housing Material & Mold

The housing serves as the “physical carrier” for battery-compatible devices. Material selection directly impacts cost, protection capabilities, and compatibility. Depending on whether dimensions are standard, cost variations are as follows:

1. Standard PVC Packaging (Flexible Packaging)

Cost Level: Lowest (Material cost only, no processing/mold costs)

Core Features: Lightweight, basic insulation only, no impact resistance/waterproofing

Size Compatibility: No mold required, fits standard cylindrical cell combinations

Applications: Low-power, unprotected small devices (e.g., micro-sensors)

2. ABS+PC Plastic Housing (Hard Shell Base Model)

Cost Level: Moderate (20%-30% higher than PVC, including materials + processing fees)

Core Features: Lightweight (40% lighter than metal), impact-resistant (withstands 1.5-meter drops), easy to process, supports basic waterproofing (IP54 rating), surface can be treated with matte finishes, spray painting, etc.

Size Options:

Standard Stock Sizes: Utilize supplier's existing molds with no tooling costs; only material and processing fees apply.

Custom Standard Sizes: Custom cavities based on standard mold bases with low tooling costs (approx. RMB 3,000–8,000), resulting in a 5%–15% surcharge.

Product Dimensions (Ultra-thin/Curved): Full-process custom molds (including mold bases, cavities, core-pulling mechanisms, etc.), mold opening fee: RMB 10,000–50,000, with an additional 20%–40% surcharge.

Applicable Scenarios: Basic protection, weight-sensitive equipment (e.g., portable medical diagnostic devices).

3. Sheet Metal Enclosure (Hard Shell Advanced Version)

Cost Level: Mid-to-High (30%-50% higher than ABS+PC, includes sheet metal cutting, bending, and spraying process fees)

Core Features: Sturdy structure, excellent heat dissipation, IP65 waterproof rating, accommodates high-power device cooling requirements.

Dimension Considerations:

Standard Sizes (Rectangular): Manufactured using standard sheet metal parts with no additional cost;

Product-Specific Dimensions (Custom mounting holes, irregular heat dissipation channels): Requires custom cutting dies and bending processes, incurring a 25%-40% cost premium

Suitable Applications: High-power, vibration-resistant equipment (e.g., AGV robots, robotic arms)

4. 304 Stainless Steel Enclosure (Hard-Shell Premium Model)

Cost Level: Highest (40%-60% higher than sheet metal, including stainless steel material, laser cutting, welding, and anti-corrosion treatment fees)

Core Features: Corrosion-resistant, explosion-proof (Ex d IIB T4), outdoor lifespan exceeding 10 years.

Size Variants:

Standard Sizes (e.g., cylindrical/square explosion-proof enclosures): Limited existing molds available, 15%-30% cost premium;

Custom Shapes/Dimensions (e.g., enclosures with specialized interfaces or integrated sensors): Full customization of molds and processes required, 40%-50% cost premium

Suitable Applications: Equipment in harsh environments (e.g., outdoor surveying/mapping, chemical testing, coastal areas with high salt fog exposure)

(4) Battery Certification

1. Basic Universal Certifications

Certification Programs: CCC, UL, CE, CB, UN38.3, etc. (selected based on export region or equipment application scenario)

Cost Explanation: Certification fees are tied to the specific testing items and the certification body (single-item certification fees typically range from several thousand to tens of thousands of yuan). Clients may handle the process themselves or entrust suppliers to act as agents; agency fees must be accounted for separately (including testing fees and service charges).

2. Industry-Specific Certifications

Certification Programs: Medical field (e.g., ISO 13485, CE-MDR); Rail transportation field (e.g., EN 50155)

Cost Note: Due to the requirement for additional specialized testing (e.g., biocompatibility, wide-temperature vibration testing), quotes will incur a 5%-15% surcharge.

(5) Purchase Volume

Volume is the “key to price negotiation.” Suppliers reduce costs by optimizing production scheduling and raw material procurement quantities. Price fluctuations are as follows:

Small batches (10-50 sets): No economies of scale, highest unit price, no room for negotiation (requires separate production scheduling, small raw material procurement volume);

Medium Batch (51-99 sets): Limited bargaining room, unit price reduction of 2%-5% (can be combined with other orders for production);

Large Batch (100+ sets): Maximum bargaining room, unit price reduction of 5%-15% (raw materials can be bulk-purchased, production runs continuously, labor costs are spread out).

(6) 24V Lithium Battery Price Reference

Lithium Iron Phosphate Battery: 24V 100Ah approx. RMB 800-1200, 24V 200Ah approx. RMB 1600-2200.

Ternary Lithium Battery: 24V 100Ah approx. RMB 1500-2000, suitable for equipment requiring high energy density.

Lithium Ternary Battery: 24V 100Ah approx. RMB 2000-3000, commonly used in low-temperature industrial applications.

Note: The above prices represent market reference rates for basic configurations only. Actual quotations require adjustment based on specific equipment requirements. Final pricing shall be determined by the formal quotation issued by the supplier according to the requested specifications.

English

English

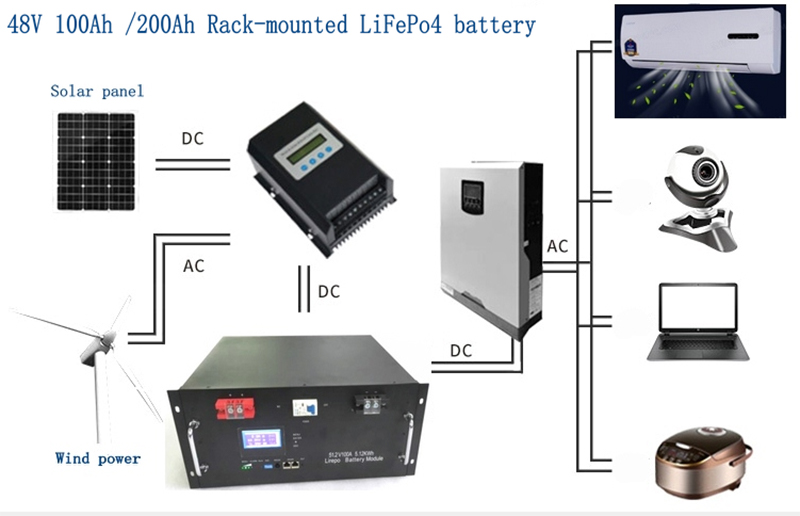

Home Energy Storage with Solar Panels: How Does It Work

As homeowners look for cleaner and more reliable ways to power their homes, combining solar panels with a home energy storage system has become an increasingly popular solution. This integrated approach allows households to generate, store, and use their own electricity, reducing dependence on the traditional power grid while improving energy resilience.

Read MoreCan a Home Battery System Power My House During a Blackout

Power outages caused by extreme weather, grid failures, or maintenance issues are becoming more frequent in many regions. As a result, homeowners are increasingly asking whether a home battery system can keep their house running during a blackout. The short answer is yes—but how much of your home it can power and for how long depends on several key factors.

Read MoreHow Much Does a Home Energy Storage System Cost

As energy prices fluctuate and renewable energy adoption accelerates, home energy storage systems are gaining attention from homeowners seeking greater energy independence and reliability. One of the most common questions is: how much does a home energy storage system actually cost? The answer depends on several factors, including system size, battery technology, installation requirements, and intended use.

Read More