Cylindrical Lithium Cell Knowledge

Cylindrical Lithium Cell Knowledge

ONE: Definition of cylindrical cell

Cylindrical lithium cells are divided into lithium iron phosphate, lithium manganese, cobalt-manganese hybrid, ternary materials of different systems, the shell is divided into two kinds of steel shell and polymer, different material system battery has different advantages. At present, the cylindrical mainly steel shell cylindrical lithium iron phosphate battery cells, the performance of this battery is high capacity, high output voltage, good charging and discharging cycle performance, stable output voltage, can be high current discharge, electrochemical stability, safe to use, wide operating temperature range, friendly to the environment, widely used in solar energy lamps and lanterns, lawn lamps and lanterns, back-up energy, power tools, toys and models.

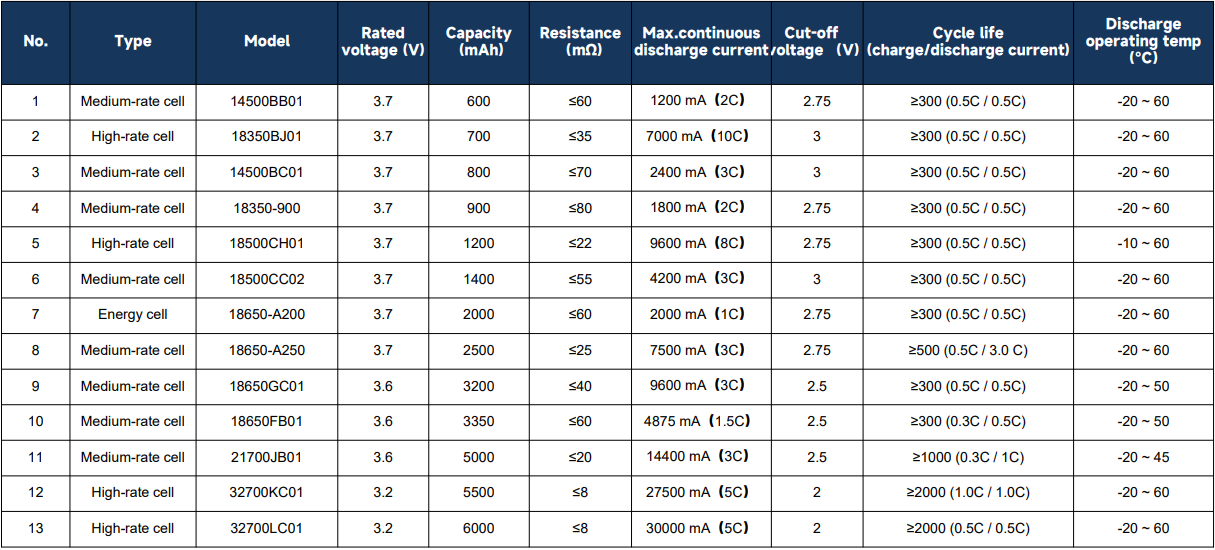

TWO: Cylindrical lithium cell model

THREE: Cylindrical cell structure

The structure of a cylindrical cell includes: shell, cap, positive pole, negative pole, diaphragm, electrolyte, PTC element, gasket, safety valve and so on. Generally, the battery shell is the negative terminal of the battery, the cap is the positive terminal of the battery, and the battery shell is made of nickel-plated steel.

IV: Cylindrical lithium cell compare with prismatic cell

1. Battery shape: prismatic cell size can be designed arbitrarily, while the cylindrical cell can’t be compared.

2. Multiplier characteristics: Cylindrical batteries welded multi-electrode process limitations, multiplier characteristics are slightly worse than prismatic multi-electrode batteries.

3. Discharge platform: using the same positive and negative materials and electrolyte lithium batteries, theoretically speaking, the discharge platform should be the same, but the prismatic lithium batteries discharge platform is slightly higher.

4. Product quality: Cylindrical battery manufacturing process is more mature, the pole piece has a low chance of secondary slitting defects, and the maturity of the winding process and the degree of automation is relatively high, the iterative process is still using a semi-manual way, which has a negative impact on the quality of the battery.

5. Lug welding: cylindrical cell lugs are easier to weld than prismatic lithium batteries; prismatic cells are prone to false welding affecting battery quality.

6. PACK into groups: cylindrical batteries have more easy to use features, so the PACK technology is simple, good heat dissipation; prismatic battery PACK to solve the problem of heat dissipation.

7. Structural characteristics: the corners of the prismatic lithium cell chemical activity is poor, long-term use of the battery energy density is easy to decline, shorter range time.

V: Comparison of cylindrical lithium batteries and lithium polymer batteries

1. Polymer batteries Better safety performance, polymer batteries in the structure of the aluminum-plastic film packaging, safety issues occur, polymer batteries generally will blow up and crack, not like steel or aluminum shell core explosion; in the safety performance is better than the cylindrical lithium batteries.

2. Polymer batteries Relatively light weight, polymer batteries weight 40% lighter than the same capacity of the steel shell lithium batteries, 20% lighter than the cylindrical aluminum lithium batteries; internal resistance is small, polymer batteries, the internal resistance of lithium batteries is small, you can greatly reduce the battery's self-consumption of electricity.

3. Polymer batteries Cycling performance is good, polymer batteries have a longer cycle life, 100 cycle attenuation is 4% to 7% less than cylindrical aluminum batteries.

4. Polymer batteries The design is more flexible, the shape can be changed to any shape, can be thinner, can be customized according to customer needs, the development of new cell models. Cylindrical lithium batteries do not have this condition.

5. Polymer batteries compared to lithium cylindrical battery shortcomings for poor consistency, high cost, prone to liquid leakage. High cost can be solved through large-scale production, liquid leakage can be solved by improving the quality of aluminum-plastic film.

English

English

Home Energy Storage with Solar Panels: How Does It Work

As homeowners look for cleaner and more reliable ways to power their homes, combining solar panels with a home energy storage system has become an increasingly popular solution. This integrated approach allows households to generate, store, and use their own electricity, reducing dependence on the traditional power grid while improving energy resilience.

Read MoreCan a Home Battery System Power My House During a Blackout

Power outages caused by extreme weather, grid failures, or maintenance issues are becoming more frequent in many regions. As a result, homeowners are increasingly asking whether a home battery system can keep their house running during a blackout. The short answer is yes—but how much of your home it can power and for how long depends on several key factors.

Read MoreHow Much Does a Home Energy Storage System Cost

As energy prices fluctuate and renewable energy adoption accelerates, home energy storage systems are gaining attention from homeowners seeking greater energy independence and reliability. One of the most common questions is: how much does a home energy storage system actually cost? The answer depends on several factors, including system size, battery technology, installation requirements, and intended use.

Read More